As

always, I will bring my Motion Cockpit IV for live demo during the complete

FSweekend 2019 in Lelystad. Please look me up in the main hall for a chat and a flight.

For the die-hards, I have installed a Carrier landing and take-off addon, please see this video. If you are up to this challenge, let me know when you visit my stand.

A video presentation of the various systems of the Motion Cockpit can be

seen here.

______________________________________________________________

Although platform III performs pretty good, it has a rather large

footprint. (about 2.5x2.5m including actuators, which takes about the whole

attic floor space). I have therefore been looking for way to reduce

the footprint, and still achieve acceptable performance. I came across

this video from

InMotion

Simulations. A particularly clever construction, that uses a triple

Sarrus linkage in a triangle setup. This construction is self-stable, can

achieve good actuator travel, while the total footprint is minimized. Due to

the scissors mechanism, the actuators have very low height in down position.

Since I don't have the US$ 35,000 I thought building one would be

quite possible, and a good challenge. (got to keep busy)

My goals for this 3DoF platform:

Single seater, payload about 160kg, weight-balanced, footprint 1.5x1.5m. Other considerations: Good response, low noise, standard materials, price about 800 Euro, most materials sourced from Taiwan.

Below pictures show a fully functional wooden scale model, (about scale

2:3)

The construction includes the balancing system, via bungee cords

that are wound on the wooden drum during platform lifting.

12V powered tests with

30kg ballast went well, no real issues discovered. (see video's) As I found out, the

triple Sarrus stability mainly determined by the bearing construction in the

wooden levers.

(This prototype was shown at FSWeekend 2009)

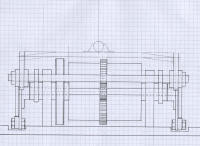

The drawings of the full scale size actuator construction are shown

below. The box is still made of wood, but the rest of the materials are

solid steel.

The crank and lever size have been optimized for max travel while keeping

the forces reasonable and travel relatively linear. Actuator travel

33cm max. Probably 30cm useful travel.

Some drive calculations:

Motor torque is 0.375Nm/A. RPM @ 36V: 936 rpm = 15.5 rounds per second.

Gear ratio belt: 3:1, Gear ratio spruce gear: 4:1

Final crank speed: 1.3 rounds per second. Actuator speed: about 33cm in 0.55

seconds (0.6m/sec), which is about the same as my #3 platform.

Torque on final crank shaft: 0.375*3*4=4.5Nm/A.

36V battery with ~ 1.5 Ohm stall resistance = 24A motor current. Final crank

shaft max torque: 108Nm. With crank arm of 7.5cm, I should get a crank force

of 1440N. Due to scissors construction, the actuator output force is reduced

to about 60%. this means max output force is 864N per actuator. Total

pushing force 2592 N.

Note this calculation assumes no losses. Actual force will be lower. But the

initial numbers are not bad.

Initial construction pictures:

Here are some pictures of the initial construction. Not all distances are

fixed yet, so some items are pending.

I have chosen to fix all parts with bolts initially. When all fits well, I

can weld the parts for more strength.

The wooden case is made of 18mm heavy duty multiplex

All gears and cranks are fixed to the shafts with 5mm keys to eliminate

backlash. The gear to gear distance is made adjustable, to be fixed in final

construction.

The side cranks are made from sprocket wheel with a steel plate bolted on. A

different plate could be used when other distances are needed.

The bearings are fixed to the sides and metal bars by means of the shaft

collars. The double bearings on the metal bar will result in a very stiff

hinge construction.

Completed crank to lever linkage. Cut-off part of the sprocket wheel.

Wooden drum made from 8 multiplex circles. Fixed to gear wheel with four M8

threaded rods.

Hit a bit of a snatch: when testing the bungee weight balance, the force

non-linearity was unacceptable. Luckily the wooden drum construction is

flexible: by changing the drum shape, a linearity correction is possible to

obtain a more constant force over actuator travel.

Some measurements are needed:

The above graph shows the (torque) rotation force on the crank top over full

actuator travel: in starts at lowest position, (crank almost at 9 o'clock as

viewed from side-view of sketch, rotating counter clockwise to max

position). It is interesting to see that the required rotation force is at

maximum when crank is at 180 degrees (3 o'clock position), and close to top,

the force quickly goes to zero.

The max required bungee counter force is 33kgf for 20kg payload, and will

need to be ~ 90kgf for 55kg payload per actuator.

It is clear that a bungee wound over the circular wooden disk is not going

to give a correct counter force. So the radius of the wooden drum has to be

modified at certain angles to compensate for the non-linear force.

After some drawings and trials, I came to the following design:

The wooden drum actually needs to be a small section only. The bungee

attaches at a point where it stabilizes the crank to its top position. This

also serves as a soft end-stop. Then when the crank rotates to the 3 o'clock

position, the bungee will pull with maximum radius, thus achieving max

opposing crank force. After further rotation, the bungee moves inward

towards the shaft, thereby reducing the radius, and reducing opposing crank

force. At crank bottom position, the bungee folds around the shaft, and

radius is minimal, so also force is minimal. The rounding edge on the

wood makes for a gradual reduction of the force. I use a quarter

section wood to be able to fasten it to the gear wheel with two long bolts.

Above pictures show the setup with single wooden drum section. Top, max

force and bottom position shown.

I have now reserved space for 10 wooden drum sections, which means 20 strings of bungee. With 8mm bungee in

linear range, I have about 4kgf of pulling force per sting in max position.

That gives totally 80kg of pulling force. Since crank arm equals radius in

max force position, I have 80kg opposing crank force which equals 80*0.6 =

48kg of actuator weight balance force. This will balance a platform

weight of 144kg.

Final touches:

Added 10-turn potmeter as position pick-up via 15-teeth gear coupled to main

gear.

Added AMETEK DC motor. It sits on a carriage that can be moved to adjust belt

tension.

Completed one actuator: Everything fits! Ready for initial drive test with 16 strings of bungee.

Initial test of single actuator under full load:

http://www.youtube.com/watch?v=OS3gkMHAgEQ

Weight balance linearity not completely correct, but overall performance

quite good.

I have been thinking a while about the most suitable type of joint for

actuator-platform. A Boge-joint that is used in wind surf boards to join the

mast and board may be suitable. They can flex in all directions, are pretty

heavy duty, and also serve as a vibration isolator, to take the really sharp

edges out of the movement. Below a picture of such a joint, they come with

M10 threaded holes on both sides.

(edit: it was found that the Boge joints are too flexible in sideward

direction. This creates unwanted lateral motion during roll or pitch), so I

used the 10mm rod-end bearing for the joints to top platform.

The rod-end bearing platform joint is fixed to the actuator top bar with M10

bolt. The platform metal V profiles are connected to the bearing with an M10

threaded rod. Two M10 nuts keep the bearing in the middle. The nuts have to

be wedge-shaped toward the bearing sides to obtain the maximum useful

bearing movement. (+/- 20 degrees)

I have spend 'some' time to learn to draw the actuator and total setup,

using the free 3D drawing program

Google SketchUp.

It helps in planning the build for the rest of the system. Below some

drawings of various assembly stages of the actuator and total setup. If you

would like to have some of the Google SketchUp CAD files, let me know.

Mounted on floor board:

Footprint: 1.26m triangle shape. Actuator distance: 1m. Max Pitch/Roll

angles: 17 degrees, max heave: 32cm.

Google sketchup file of one actuator can be downloaded

here.

For some sense of scale, I added a real size pilot: It shows the compact

size of the actuator setup.

After lots of metal drilling and sawdust, all three actuators are

finished. Also cut the floorboards.

Mounted the top triangle frame. I used 10mm rod-end bearing for the

joints. (the rubber Boge joints were too flexible). The final structure is

sturdy and stiff in all directions.

Also added the full bungee weight-balance strings. I found that the original

setup overstretched the bungee, so I folded the bungee to increase length.

Each actuator now uses 13m of 8mm bungee cord for 50kg weight balance per

actuator.

After completion of the "Modular Simpit"

a quick try to see if everything fits:

Original drawing ceiling has

sufficient margin Good balance, no need to tighten the

bungees.

Tests with new PC show good performance. Servo gain needs to be reduced

due to less friction in the system.

See

initial test video

The rig also survived FSweekend 2010: 2 days of continuous use with some abuse from less skilled pilots. Structure is sound and robust.