For DIY Motion Platform III, the electrical motion drive needed to be

expanded to 3 channels. The small signal concept was not altered, but the

MOSFET half-bridge was changed into full bridge. (H-bridge). The DAC

converter was expanded to 4 channel version.

Full schematics and PCB layout are at the bottom of the page.

Build or Buy?

Although the circuit is not extremely complex, it can be tricky to get it to

work properly. It took me a couple of re-layouts and several modifications

to get it stable. Since it consists of both sensitive digital circuits and

high current switching power stages, the layout is extremely

important. If you have some experience in building these kind of circuits,

it's good fun and will probably work. Without any knowledge of power

electronics, and no oscilloscope to do troubleshooting, I would recommend to

buy commercial motor drivers.

Info on commercial motor drive:

http://buggies.builtforfun.co.uk/Sim/wiring.html

http://www.roboteq.com/

http://www.parallax.com/detail.asp?product_id=29144

Price-wise, you'll probably be cheaper building this circuit than buying

three motor drivers, but this depends a lot on the price you can get the

components listed. Farnell is very expensive, but there must be others that

offer the components for more reasonable price.

Circuit explanation:

The driving signals for the IC are made such that there is some dead-time

between the switch-off of one Mosfet and switch-on of the other. Without

sufficient dead time, the two Mosfets could conduct simultaneously, shorting

out the supply, thereby killing both Fets.

The working of the high and low side Mosfet drive is shown above:

The drive and

position feedback are added together. The output of the opamp drives the

inputs of two comparators, where the resistor network takes care that there

is a small offset between the two comparators inputs. The other inputs of

the comparators are driven by a triangle waveform. (actually it's a sawtooth but

it does not make a difference)

The resulting outputs of the comparators is shown at the right. Moving the

DC voltages up will result in longer on-times of the low side Mosfet and

shorter On times for the Hi-side Mosfet and visa versa. The dead time between two transitions

will remain constant.

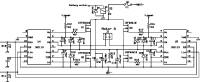

The H-bridge circuit is show above. Each high-side Mosfet drive has it's own floating supply.

This time I have made use of the

bootstrap trick as shown in the IC spec. but I needed to add a special bias

resistor (R12 and R16 via Vboost) to make sure that the Hi-side Mosfet

floating supply will remain, also in 100% duty cycle conditions. Vboost is a

voltage that is about 18V higher than the +BAT voltage. With this solution, the Mosfet drive always has correct gate

drive supply, regardless the switching conditions. Diodes D19 and D20 proved

necessary to protect the drive IC's from negative spikes. Although the

H-bridge circuit has about double the component count of the half-bridge,

it has the advantage that it needs only one single positive BAT supply, which does

not need current sink capabilities.

** Update version 2.3: I have replaced the IRFP250 by IRFB4610. They have

lower Rdson, but more importantly they have very fast body diodes and are

especially designed for hard-switching configuration.

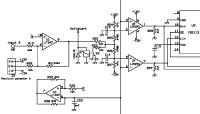

A part of the small signal section of the Motion drive is shown above. Some

resistor values may need to be modified depending on the amount of actuator

travel and the gear-ratio of the Position potmeter pickup.

R19 sets the input gain. Bigger values mean lower gain.

R20 sets the servo "stiffness". Lower values may make the system instable,

higher value may make the platform positioning less fast and less accurate.

A change compared to the previous circuit is the implementation of

soft-start: Now this is implemented in the small-signal chain. (S3 and R23).

During start-up, the relay is not activated, and R23 attenuates the error

signal in such a way that the platform has only limited driving capability

to move to the center point. When the softstart signal goes high, the relay

switches off R23 and full drive speed is enabled.

** Update version 2.3: I have reduced the dead-time by lowering the values

for R25/R26. This reduces dissipation in the MOSFETS. Dead-time of all 3

bridges need to be reduced, see full schematic at the bottom.

The power supply of the Motion Driver is show above. Standard + and - 15V for the small signal supply. The delay for Battery switch and Soft-start relays are such that the Battery power will be enabled 1 sec after the start-stop and end-stop switches are all closed. The Softstart relay will be activated after about 8 seconds, which is sufficient to let the platform move slowly to the correct position. Indication of various states is done via LED's. Opening one on the end switches or Start-Stop switch will immediately switch-off the battery supply. Mount the Start-Stop switch in a easily reachable position as it could be needed in emergency cases.

Note that the H-bridge Battery minus is connected to Small Signal -15V.

The Vboost supply is taken from a floating winding in the transformer

connected to the Positive battery supply, to give the H-Bridge a bias

voltage which is always 18V higher than the +BAT supply.

The interfacing still makes use of the parallel port. For this platform I

have build a 4 channel parallel port DAC (the max that is possible). Three

DAC's are used for driving the 3 motors of the platform, an extra DAC can be

used for other purposes. (i.e. control an electric fan for wind effect

depending on airspeed, or controlling a vibration unit based on engine RPM).

Above, one channel of the 4-channel DAC circuit is shown.

Four control bits C1...C4 are used to latch each IC. The R/2R network signal

is fed to an Op-Amp, which now also has a zero adjust function.

Capacitor C10 can be increased to make the DAC response slower. The shown

220nF will result in very fast DAC response. Depending on the software

update speed, some digital noise may be felt in the motion drive. A larger

value (470nF .. 2.2uF) will filter this noise.

Adjust for

0V DAC_A output when sending 128 (80Hex) and activating (low-high-low) the C1

bit.

Note that the DAC PCB has its own supply via 5V regulator.

The control bits have a pull-up resistor to obtain better latch waveform shape with

fast pulses.

Updated version 2.3 motion drive

schematic

and motion drive PCB layout

Updated version 2.0 4 channel DAC

schematic

and 4 channel DAC PCB layout

These are 2 boards that can be connected together, or used stand-alone for other applications.