After reviewing the various motion systems and actuator possibilities, I finally came up with a design that would fit in a corner of our study.

The biggest challenge of the project was explaining to the wife that this

was an important experiment that just had to be tried out.

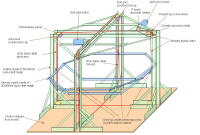

The above drawing shows the principle of the motion system: A platform,

suspended in cables, making roll and pitch movements possible. The advantage

of this type is that the user is positioned quite close to the rotation

points. The trick to low driving power and good response is to weight balance the inner frame:

The motor drive just has to deliver enough power to overcome the inertia of

the moving platform mass.

The size of the whole contraption depends on the amount of gear you want to

put in the moving cradle. The height is mainly determined by your own body

extremes, where your head / feet will touch the top beams / floor when

pitching down. I designed this thing in a 'sit-up straight' pilot position.

Lower height could be possible when sitting in a reclined seat position

(like in my Simpit where your feet

are almost the same level as the chair.

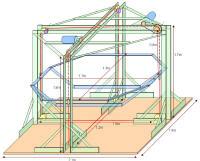

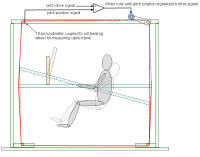

The motion drive principle is shown above: The cradle, suspended in cables

will tilt one way or the other when the motor rotates the sprocket wheels.

The cable runs over roll-bearing wheels on the 3 other corners. Since the

cable turns these wheels as well, cable travel (= cradle angle) can be

derived from the rotation of the corner wheels. A 10-turn potmeter geared to

one of the wheels can provide the electrical signal for cradle tilt. The motor drive

system is basically a servo system where the motor turns in such a way that

the position signal always equals the tilt drive signal. The pitch or roll

drive signal thus has to be an analog varying voltage.

Below some pictures of the construction:

Basic structure showing the basic frame, cradle suspension and top section,

motors not yet installed

Top and side view of roll axis motor driving sprocket wheel

Detail of position feedback potmeter and end-stop switch

End-stop is a must-have protection that switches off the supply to the motor

drives when the platform exceeds the maximum tilt angle. This could happen

when there is a failure in the motor drive circuit.

The end-stop is simply a wire on the cable, that activates a micro switch

when the wire is pulled too low. There are two switches for every axis; each

cable bottom corner has an end-stop switch.

During construction, there was a lot of tweaking required. Here you see the

platform with CRT monitor, seat, cockpit console, and three 20 liter water bottles to

simulate my weight.

---- Motion Video's -----

From the above setup, I have two video's showing the platform movements:

Motion platform intro and

Motion platform washout

In these video's I had the yoke console placed separate, as I was in the

middle of a tweaking session.

(The video was shot by a Dutch friend of mine, so explanation is also in

Dutch)

The final setup looked like this: LCD monitor with freshnel lens, and a

tent-like construction to block the view from the room. Using LCD in stead

of CRT monitor saves some weight, which improves the platform response.

This is me trying out the system.

The experience: The climbing and descending feels pretty good when

tilting up or down. Especially during take-off, the rotation and

backpressure is quite convincing.

Also the small bumps and vibration adds a lot to the experience.

The only disadvantage is that during a take-off rotation, you feel that you

are not only rotating, but also going down, as if you were sitting in the

last seat row of a big airliner during take-off.

Roll motion is not so convincing, as you fall out of your chair when adding roll. Even a short differential signal (just a small roll spike with slow return to center does not feel right. The whole movement needs a lot of experimenting. That's the good thing about electric drive, it is very flexible in input tweaking.

I had a breadboard on the platform, and was checking the possibilities of

passive & active filters, with 'sort of' correct washout (return to center).

The possibilities of interface that I have checked with this platform:

Direct from the yoke, throttle, brake (I'm using dual potmeters, and then it

is easy to take a differential signal from the control input)

Mixed in some signals from the force feedback yoke.

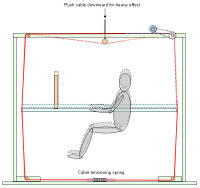

Adding Heave

A possibility for adding some heave (vertical movement) is shown above. In

principle both cables should be pushed simultaneously. There will be a small

pitch/roll error generated, but that could be easily compensated.